As a technical benchmark and standard-setter in the metallurgical gas sector, MCC Huatian has achieved another key milestone in the operation and diagnostics of "Smart Pipeline Networks." Significant progress has recently been made in the sub-project "Intelligent Gas Dispatch and Prediction System," led by MCC Huatian in collaboration with Baowu Ma Steel Changjiang Steel. The project has achieved breakthroughs in critical areas including high-flow velocity warning, abnormal pressure location, and resistance bottleneck identification. It has also developed capabilities in condensate calculation and dynamic response simulation, addressing several technological gaps in China. This represents a fundamental shift from "passive response" to "active prediction," laying a solid foundation for post-holiday model training. Furthermore, the overall project won the "Gold Project" award at the second Anhui Province Employee Innovation Competition and received special funding, fully demonstrating its innovative and practical value. This sets a new benchmark for intelligent energy management in the industry and reinforces MCC Huatian's leadership in this field.

With over four decades of experience in the steel industry gas sector, MCC Huatian has drafted several national and industry standards, including the "Design Code for Gas Storage and Transportation Systems in Iron and Steel Enterprises." It holds the leading domestic market share for single-stage rubber membrane sealed gas holders and has completed over 200 benchmark projects, showcasing its technical strength. To address the industry's common shortfall where conventional gas control systems only provide data visualization without core intelligent predictive capabilities, MCC Huatian initiated a key R&D project at the end of 2024. The project involves collaboration with top universities to establish an "industry-academia-research-application" system focused on tackling core industry challenges. In 2025, MCC Huatian entered a strategic partnership with Anhui Changjiang Steel on this project. As a core enterprise of China Baowu and a benchmark for full-process steelmaking, Anhui Changjiang Steel is actively promoting the intelligent upgrade of its energy systems. Based on shared objectives, the two parties collaborated on this initiative. The R&D team conducted on-site data collection and carried out customized development tailored to Changjiang Steel's specific pipeline network layout and production characteristics to ensure the technology's high compatibility with the operational environment.

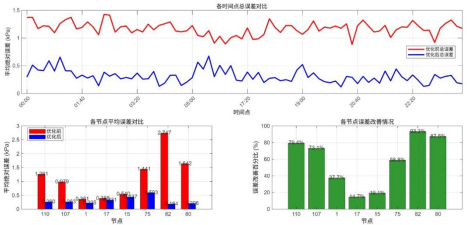

Moving beyond traditional approaches, this R&D project focuses on full-process intelligent optimization. It constructs a 1:1 digital twin model of the pipeline network, deeply integrating fluid dynamics algorithms with advanced AI prediction technologies. Surpassing the limitations of conventional machine learning, it achieves core functions such as production-consumption forecasting, dynamic optimization, and decision support. This transforms gas holders into the core hub for energy storage and dispatch within steel enterprises, enabling precise "inflow" and "outflow" energy management. Compared to conventional data acquisition-based control systems, it offers significant technical advantages. It performs real-time simulation to calculate pressure distribution across the entire network, with a relative error between calculated and measured values of less than 2%, ensuring pipeline safety and reducing gas flaring.

Looking ahead, upon implementation, the system will help enterprises achieve precise forecasting and consumption control of their gas systems, meeting goals of cost reduction, efficiency improvement, energy conservation, and carbon emission reduction. MCC Huatian will use this project as a blueprint to promote its core technologies, continuously driving the industry's transformation towards "Smart Pipeline Networks" and providing momentum for the green, low-carbon transition of the steel industry and the broader industrial sector.