MCC Huatian's Blast Furnace Gas Precision Desulfurization Technology Yields Tangible Success

Recently, in the emerging global field of blast furnace gas precision desulfurization, MCC Huatian successfully secured the EPC project for the blast furnace gas precision desulfurization system at Sha Steel Group's 180MW thermal power plant. This collaboration with Sha Steel marks a significant leap from technological R&D to large-scale industrial application, built upon years of dedicated efforts. It not only reflects the trust of a leading steel enterprise in the "Huatian Solution" but also serves as a successful validation and high recognition from the metallurgical environmental protection market for its innovative gas purification achievements. This will effectively drive the iterative innovation of gas purification technology in the steel industry, empowering the entire industrial chain's value leap with more efficient and cleaner solutions.

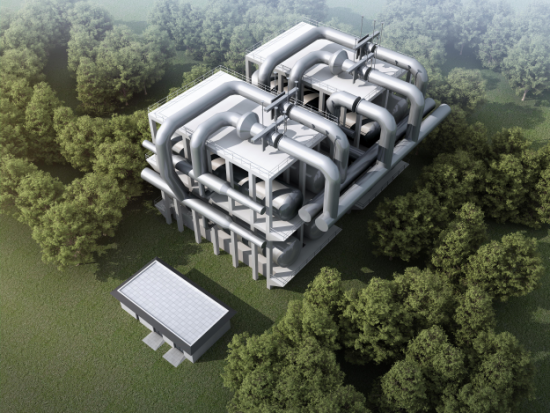

The project employs an innovative "catalytic hydrolysis + deep adsorption" process, ensuring low energy consumption, high efficiency, and long operational cycles. Designed for Sha Steel's space constraints and strict requirements for efficiency, stability, and energy conservation, this compact system reduces resistance, avoids secondary pollution, and allows modular integration with minimal disruption to existing operations. Once operational, it will enable near-zero sulfur dioxide emissions from the power plant's gas combustion, supporting Sha Steel's clean production goals and strengthening MCC Huatian's position in the BFG treatment market.

BFG is a by-product gas in steelmaking, and its clean use is crucial for ultra-low emissions. Traditional "end-of-pipe" treatment methods are often complex, energy-intensive, and prone to secondary pollution. To address this, MCC Huatian's Industrial Environment & Energy Division formed a dedicated team. Led by technical expert Liu Xiangpeng, the team conducted extensive on-site testing and optimization under challenging conditions, gathering critical data for technological breakthroughs.

After nearly a decade of development, the team has established a reliable BFG desulfurization process centered on "catalytic hydrolysis + dry desulfurization." MCC Huatian has built a complete intellectual property portfolio around this technology, with 16 patents covering core materials, equipment, and system integration. The key provincial R&D project, "Research and Application of Catalytic Hydrolysis Removal Technology for Carbonyl Sulfur in Blast Furnace Gas," has passed expert review, confirming the technology's maturity. In 2024, the first industrial-scale installation using this technology commenced stable operation in Shanxi, demonstrating its transition from lab to practical application.

Moving forward, MCC Huatian will continue to focus on clean energy and industrial environmental needs, leveraging its expertise in gas treatment to provide smarter, cleaner solutions and support the industry's green transition.