Strategic Collaboration Powers Successful Launch of 12MW Unit at Sha Steel with MCC Huatian's Pipeline Diagnosis Technology

On January 15, 2026, the 12MW saturated steam generating unit at the Zhangjiagang production base of Jiangsu Sha Steel Group, supported by MCC Huatian's comprehensive pipeline diagnosis technology throughout the entire process, commenced operation smoothly and achieved stable full-load operation. This successful launch not only marks a significant breakthrough for Sha Steel in the cascaded utilization of steam energy but also serves as a benchmark validation of MCC Huatian's full-process pipeline diagnostic capabilities. Its proprietary millimeter-level precision diagnosis system and the closed-loop service model encompassing "diagnosis-planning-design-construction-operation" once again demonstrate MCC Huatian's technical leadership in pipeline diagnostics within the metallurgical industry.

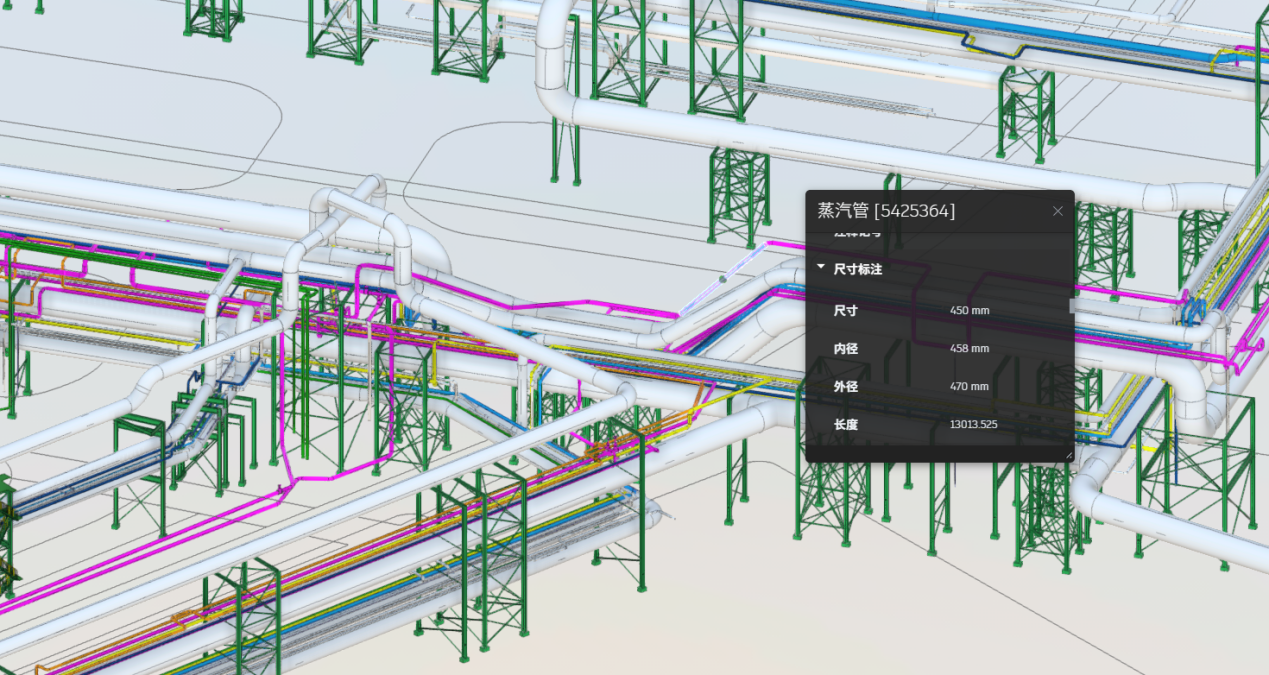

The energy pipeline networks of metallurgical enterprises, often referred to as the "industrial lifeline," directly impact energy consumption, production costs, and operational safety. However, the industry commonly faces challenges characterized by "lack of visibility, unclear calculations, and poor regulation." The Sha Steel Zhangjiagang base, for instance, grappled with issues such as large plant area, dispersed steam production and consumption units, complex pipeline layout, and numerous drainage points. Traditional survey methods were not only inefficient and data-inaccurate but also inadequate for plant-wide integrated planning and systematic simulation analysis, severely hindering improvements in energy utilization efficiency. In this context, Sha Steel decisively adopted MCC Huatian's core technology—the holographic 3D pipeline diagnosis system—seeking a systematic solution.

As one of the few engineering service providers in China's metallurgical industry mastering omni-medium spatial 3D digital pipeline diagnosis technology, MCC Huatian formed a specialized technical team. Leveraging its independently developed holographic 3D digital modeling technology system, the team provided full-process diagnostic services for the Sha Steel project. By innovatively integrating technologies like 3D laser scanning, UAV surveying, and infrared thermal imaging, the team achieved millimeter-level precision reconstruction and comprehensive data collection for nearly 70 kilometers of pipelines across the plant, with errors strictly controlled within the millimeter range. Based on the collected vast and precise data, a "digital twin" model of the steam system was constructed. Through comprehensive simulation analysis, core issues such as pipeline redundancy loss points and pressure imbalance points were accurately identified, leading to the generation of multi-dimensional optimization plans. This effectively addressed the "data silos" and delayed response problems inherent in traditional diagnostics. Furthermore, utilizing its self-developed lightweight 3D platform and mobile inspection tools, MCC Huatian enabled offline model viewing and problem pinpointing, providing solid data support for subsequent rectification planning and engineering design. This approach seamlessly covered the entire process from "diagnosis-planning-design-construction-operation," establishing a replicable and promotable closed-loop service model.

The successfully launched 12MW generating unit is the core embodiment of the transformation of MCC Huatian's precise diagnostic results into tangible outcomes. The unit completed commissioning on January 15, 2026, with its key operational indicators surpassing design expectations. Its smooth operation not only efficiently utilizes the plant's surplus steam resources but also achieves pipeline pressure balance and highly efficient cascaded energy conversion, significantly improving comprehensive energy utilization efficiency and supporting Sha Steel's strategy for ultimate energy efficiency and green, low-carbon development. This success also validates the core supporting role of MCC Huatian's diagnostic technology in the digital transformation of existing steel enterprises.

A relevant person in charge of Sha Steel stated that the successful full-capacity operation of the new unit is primarily attributed to MCC Huatian's millimeter-level precision diagnosis technology and full-process closed-loop service. The closed-loop implementation at Sha Steel is a significant milestone for the large-scale promotion of the company's technological achievements. Moving forward, the company will continue to deepen industry-academia-research collaboration, refine its digital diagnostic technology system, accelerate the implementation and transformation of technological achievements within the metallurgical industry, empower more industrial enterprises to achieve efficient energy utilization and green, low-carbon transformation with new quality productive forces, and showcase the leading role of central state-owned enterprises in industry upgrading.