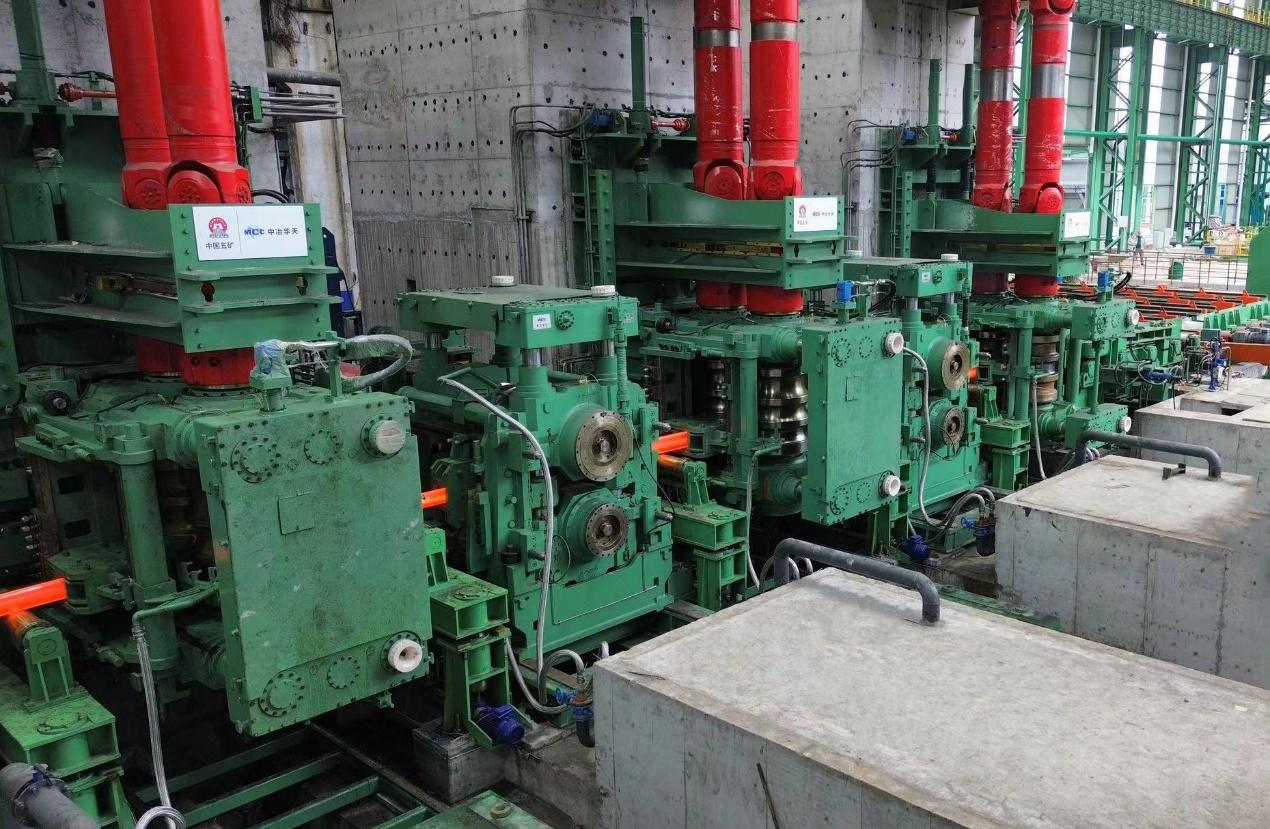

- A new 1350 blooming mill, the largest of its type for tool/die steel lines, capable of processing over 400 grades of special steel and alloys.

- A world-first continuous rolling mill that works in tandem with the blooming mill to significantly raise throughput.

- A large hydraulic shear—first in China—enabling precise online cutting, integrated with descaling, deburring and automatic bundling.

Since trial production, the equipment has proven reliable under high-intensity, multi-variety operation. Annual capacity has risen from 220,000 tons to 345,000 tons, supporting the record self-smelted steel output.

Intelligent System Enhances Operations: A custom smart control platform drives the line’s shift from mechanical to intelligent operation. It integrates full-line PLC and L2 rolling control, featuring:

- Automated process control and scheduling via MES.

- Data analytics for predictive maintenance, cutting unplanned downtime.

- Continuous on-site optimization, improving response speed and control accuracy.

The system has helped reduce cost per ton and raised the yield rate of self-smelted steel by over 2.2 percentage points.

Product Development Expands Capabilities: The line now accommodates a wide range of special steels. Through systematic trials, most products meet or exceed specifications in dimensions, straightness, surface quality and mechanical properties. For example, tool steel Cr12MoV achieves a yield rate ≥82%. While a few extreme specifications are still under development, the line stably produces most grades, enabling faster market response.

The upgrade has strengthened Pangang Changte’s in-house steelmaking, lowered costs via rolling-forging substitution, and improved profitability. Its high-temperature alloys and high-strength steels are used in strategic sectors such as aerospace, heavy-duty turbines and marine engineering.

This project demonstrates how advanced hardware paired with intelligent control can drive production breakthroughs. The upgraded line is now a core asset for Pangang Changte’s growth, and MCC Huatian continues to support the industry’s shift toward smarter, greener production.