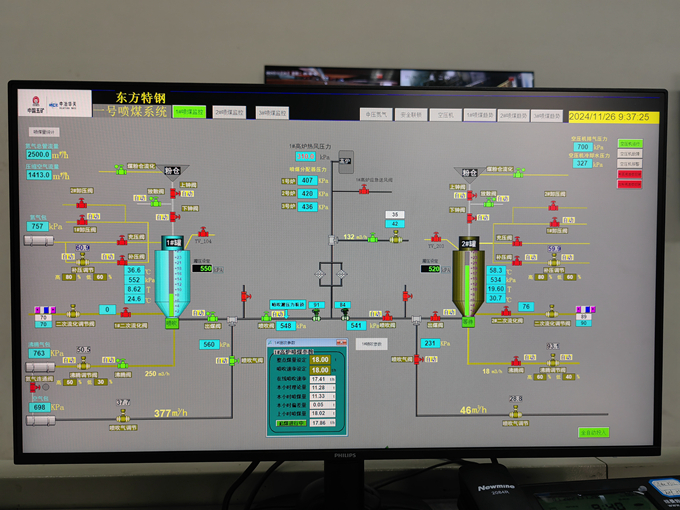

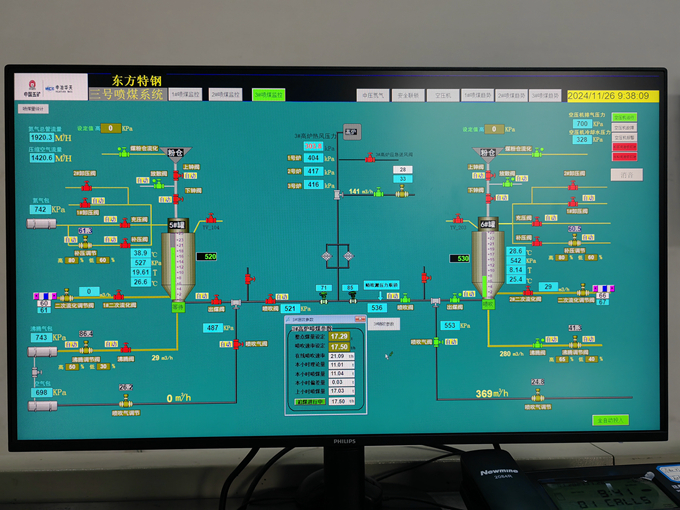

With the commissioning of the supplemental air system for the main pipeline of the No. 2 injection system, the "One-Key Injection" technological retrofit project for the pulverized coal injection system at Changzhou Oriental Special Steel Ironworks, undertaken by MCC Huatian on an EPC basis, was fully and successfully put into operation. The injection process runs smoothly, with all errors controlled within the range specified in the technical agreement. The steady progress of this project enhances MCC Huatian's competitiveness and project execution capabilities in the field of blast furnace pulverized coal injection technology, accumulating valuable experience for subsequent similar projects. It also serves as a practical response to the "60-Day Sprint, Achieving Annual Peak" initiative.

It is reported that the project primarily involved the supply, installation, software programming, and debugging of equipment within the scope of retrofitting three injection systems to meet the requirements of automated and intelligent uniform injection. Upon completion, the project significantly improves the intelligent level of the owner's ironmaking system.

In July of this year, after receiving information about the project, the project team actively engaged in technical exchanges with the owner and arranged for the owner to conduct on-site inspections of similar completed projects. Ultimately, an EPC contract was signed with the owner in September.

This project is a third-tier operating project of the company's Steel Division and also the first technological retrofit project for a single pulverized coal injection system undertaken by the company. With its limited scope of specialized disciplines and tight timeline, the challenges were considerable. During project execution, to complete the installation of new equipment for the three injection systems during the owner's overhaul of the No. 2 blast furnace without affecting the normal operation of the No. 1 and No. 3 injection systems, the on-site project team communicated with the owner in advance, reasonably arranged the construction sequence, and employed off-site prefabrication and pre-assembly methods to complete the installation of new equipment and pipelines for the three systems on schedule. During the debugging phase, due to differences in the owner's operational habits and certain interlock requirements compared to the original design program, the programming designers made significant on-site modifications to the program to meet the owner's needs.

The project team will continue to ensure proper project closure while actively engaging in new projects, contributing to the company's efforts to fully achieve its annual targets.