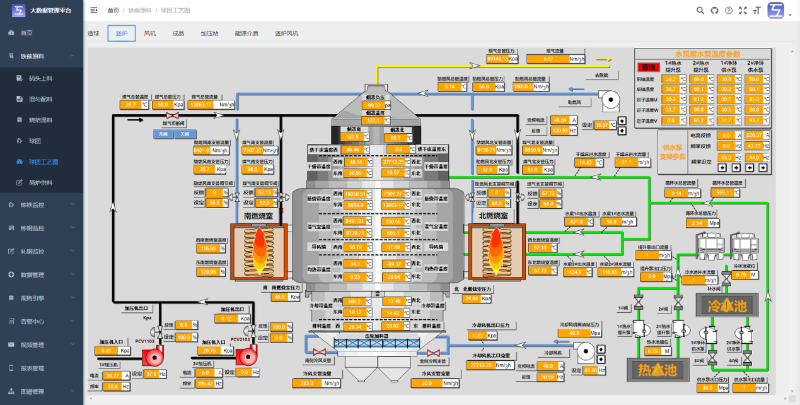

On June 9, MCC Huatian Nanjing Electric (Internet+) officially launched its self-developed IoT big data platform, which has been successfully applied to the remote online monitoring of the pelletizing process section of Fujian Sanbao Steel Co., Ltd. This self-developed IoT big data platform can be regarded as the cornerstone of intelligent construction service applications to provide integrated data management, data analysis and decision support for green and intelligent construction and smart operation of terminals in multiple industries such as steel, water environment, health care, smart cities or parks. This is another breakthrough made by Nanjing Electric in the intelligent iron & steel applications following Rizhao Steel's intelligent stockyard and Shagang's intelligent control center, contributing to the construction of "Digital MCC Huatian".

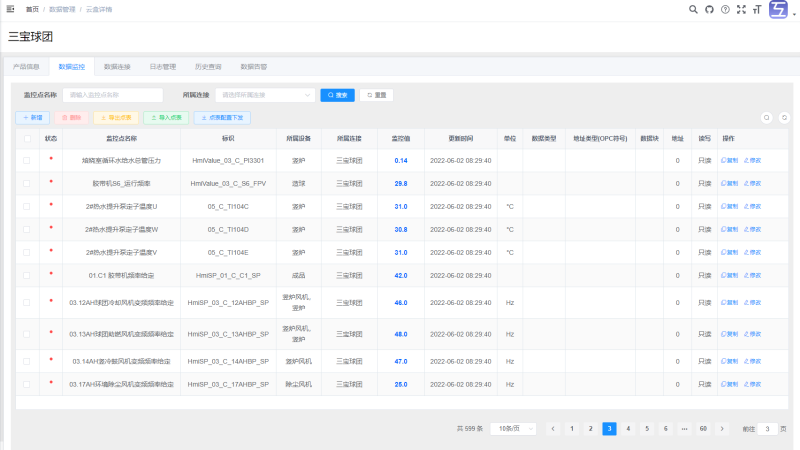

The whole platform consists of distributed multi-source data acquisition module, multi-protocol high-frequency real-time data transmission module, large-capacity cluster time series data storage module, process-based data cleaning, analysis and display module, and third-party platform data sharing module. The platform supports multiple acquisition protocols, including industrial control acquisition protocols such as Siemens, Delta, Schneider, OPCUA, ModbusTCP, ModbusRTU, MQTT, and HJ212-2017 commonly used in industrial sites; multiple access forwarding, including self-developed devices, third-party multi-terminals, gateway, as well as MQTT, HTTP, WEBSOCKET, Kafka, etc.; multiple data storage, including memory database, time series database, structured database, graph database, log library, etc.; and multiple system functions, including controllable remote configuration of collection points, real-time online data monitoring, storage management of time series data, rule engine alarm center, drag-and-drop report analysis, intelligent video recognition and analysis, data mining prediction, three-level authority control, traceable log management, etc. In addition, the remote mobile monitoring APP and the self-developed multi-functional intelligent access gateway were also launched simultaneously with the platform. The coordination of software and hardware can build a terminal-to-terminal complete solution, which has higher efficiency, lower latency and faster processing speed in data collection and analysis, and is scalable, enabling enterprises to form an integrated digital solution of “cloud-network-edge-terminal”.

The platform has been developed since June 2021. The MCC Huatian Nanjing Electric (Internet +) team has carried out thorough technical research, feasibility design and review, system scheme design and review, detailed module design, and test optimization. Based on years of engineering project experience, the team took nearly half a year to conduct research and development and tackle key problems. Under the support and care of the leaders and experts of Nanjing Electric and the unremitting efforts of the team, the platform was finally officially launched and successfully operated on the remote online monitoring of pelletizing process section of Fujian Sanbao Steel Co., Ltd.